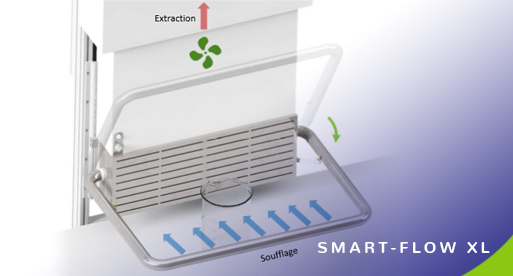

The new generation extractor hood XL captures harmful steam and fumes at source !

After smart-Flow weigh station's success in laboratories as well as digital simulations, our R&D team has developed smart-Flow XL, an extractor hood that captures 99% of pollutants. Its promise: lowering harmful effects from CMR (Carcinogenic, Mutagenic, Reprotoxic) substances on your operators while ensuring an optimal accuracy during the weighing of these products. Conceived without draft shield, smart-Flow XL allows a more comfortable position for the operator who performs recurring weighings, handlings, welds... At the end of each of the operation, the hood automatically switches off in order to reduce the energy expenses; exploitation costs are then divided by 30.

smart-Flow XL’s strength

• Indicator light when operating

• Warning light

• Starting up sensor

• Switch for ventilation settings defined according to the needs

• Activation of the ventilation by a swivel arm

• Control and regulation of the flow rate

• Flow rate alerts

• Fan blower with variable air flow rate

• Air speed: 0,5m/s

• Sensor for differential pressure

• Analogic throttle damper for extraction flow

• Exhaust ventilation fan with variable speed (V option)

• Adjustable captation height (MBE option)

• 110/230 VAC power supply

• On-board control/command system

• Electrical protections

• RJ45 Ethernet connector (E option)

• Wifi device (W option)