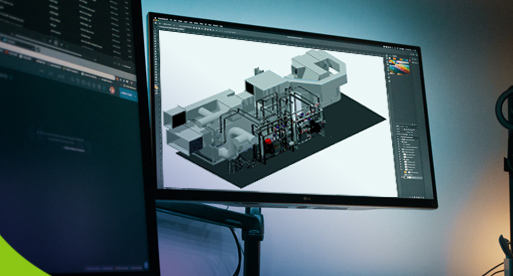

In order to support our industrial clients, we built a 1000 square meter workshop where we offer customized solutions and accurate sizing. Our prefabricated systems are tested, approved before disassembly and integrated in real environment through 3D simulations beforehand. We undertake a mapping of the location in advance to insure turnkey solutions, of all sizes, suitable to our clients’ expectations and environment.

Through 3D scan, we collect accurate data to conceive the best solution for you, as soon as possible.

By spending the least amount of time on your work site, we prevent heavy disturbances for your activity, thus optimizing your productivity.

Carrying out the fabrication in our sheltered workshop allows us to offer you qualitative equipment, not subjected to unexpected hazards or delays due to weather conditions.

We are onsite solely for the assembly of your solution, therefore preventing your from stopping or slowing down your productivity for too long.

Our workers are familiar with accident prevention measures and safety norms. Work coordinators also supervise our teams daily.

We handle the management of waste and pollutants produced on our work sites, in order to limit our environmental impact.